Table of Contents

- The Ultimate Guide to Understanding 3D Printers and Their Capabilities

- Innovative Ways 3D Printing Can Revolutionize Manufacturing Processes

- From Jewelry to Medical Devices, Here’s What 3D Printers Can Create

- How 3D Printing is Transforming the Architecture and Construction Industry

- Creating Customized Prosthetic Limbs with the Help of a 3D Printer

- The Future of 3D Printed Food: A Look into the Culinary Industry

- Breaking Boundaries with 3D Printing: Exploring the Limitless Possibilities

- People Also Ask

- Conclusion

Have you ever heard of a 3D printer and wondered what they could do? These incredible machines are capable of creating intricate, complex objects with incredible precision and accuracy.

You might be surprised at the variety of objects that 3D printers can produce, from simple toys to complex medical equipment, and even entire buildings. In this article, we’ll explore the capabilities of 3D printers and show you some of the amazing things they can do.

Whether you’re a curious hobbyist or a business owner looking to explore the world of 3D printing, this article will give you a glimpse into the exciting possibilities of this technology.

The Ultimate Guide to Understanding 3D Printers and Their Capabilities

When people think of 3D printers, they often imagine simple plastic objects like toys or decorations. However, these devices are capable of creating much more than that. In this article, we will explore the various possibilities that 3D printing technology offers.

What is a 3D printer?

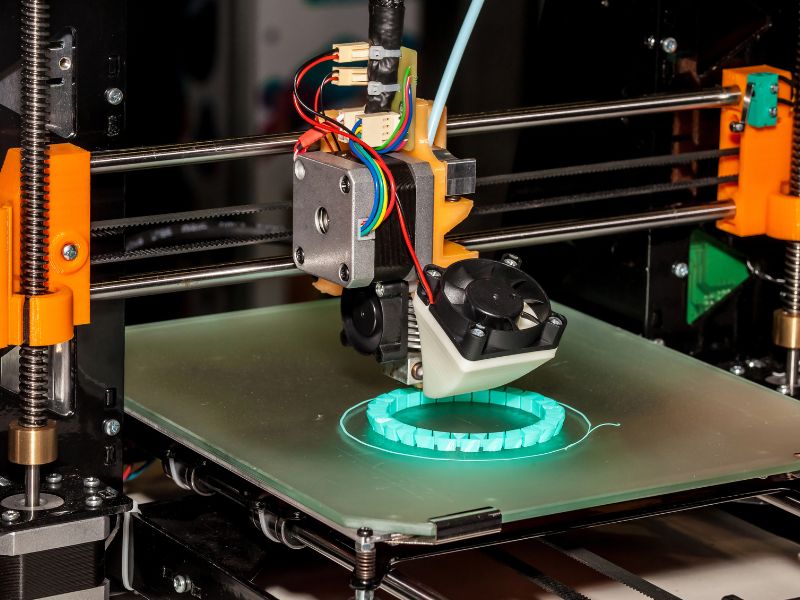

A 3D printer is a type of additive manufacturing technology. It builds objects layer by layer using a digital file as a blueprint. This is in contrast to subtractive manufacturing, which involves cutting and shaping a material to create an object.

What materials can be used in 3D printing?

3D printers can use a variety of materials, including plastics, metals, and even food. Some popular materials for 3D printing include PLA, ABS, nylon, and resin. The type of material used will depend on the intended use of the printed object.

What kind of objects can be created with a 3D printer?

The possibilities are endless! Some of the most popular applications of 3D printing include manufacturing prototypes, creating customized medical implants, building houses and other structures, and producing complex jewelry and fashion pieces.

3D printing is also being used in educational settings to teach complex concepts through tangible objects.

This guide has only scratched the surface of what 3D printing can do. As technology continues to evolve and improve, we can expect to see even more exciting applications of this revolutionary technology.

Innovative Ways 3D Printing Can Revolutionize Manufacturing Processes

3D printing, also known as additive manufacturing, is a game-changing technology that has the potential to transform the manufacturing industry.

Instead of traditional subtractive methods, which involve removing material from a block until what remains is the final product, 3D printing builds the product layer by layer from digital designs.

The Benefits of 3D Printing for Manufacturing

One of the most significant benefits of 3D printing in manufacturing is its ability to reduce costs and increase efficiency. With traditional manufacturing processes, companies typically need to produce large volumes of a product to make it cost-effective.

However, with 3D printing, manufacturers can produce smaller quantities of specialized items while still being cost-effective. This means that companies can produce products on demand and reduce the need for large storage spaces and expensive tooling.

Another benefit of 3D printing in manufacturing is its ability to produce complex and customized designs. Since 3D printing builds products layer by layer, it can create intricate shapes and designs that are impossible or challenging to produce with traditional manufacturing methods.

For example, aerospace manufacturers can use 3D printing to create parts with internal cooling channels for efficient fuel management that would be difficult to create with traditional machining methods.

Applications of 3D Printing in Manufacturing

The possibilities for using 3D printing in manufacturing are nearly endless. Some of the most common applications include creating prototypes quickly and cost-effectively, producing customized medical implants and devices, and printing replacement parts for machinery.

3D printing is even being used to create entire buildings and construction components, revolutionizing the construction industry.

One lesser-known application of 3D printing in manufacturing is with specialized or unique materials. Materials such as carbon fiber and titanium are challenging to work with through traditional manufacturing processes but can be easily and cost-effectively printed with 3D printing.

This opens up new possibilities for manufacturers to use advanced materials in their products.

From Jewelry to Medical Devices, Here’s What 3D Printers Can Create

From creating intricate pieces of jewelry to producing complex medical devices, the possibilities with 3D printers are endless. With technology constantly evolving, 3D printing has become an invaluable tool for industries looking to streamline production processes and create unique, customized products.

Jewelry designers are using 3D printers to produce intricate and unique pieces at a much faster rate than traditional jewelry-making methods. The technology allows for the creation of complex shapes and designs that were once thought impossible to create by hand.

Using the printer, designers can produce a wax mold of the piece, which is then used in the casting process, resulting in a finished product that is both intricate and durable.

In the medical field, 3D printing is revolutionizing the way doctors and surgeons approach patient care. Using 3D printers, medical professionals can create customized implants and prosthetics to fit the specific needs of their patients.

These devices can be produced quickly and accurately, reducing the time and cost associated with traditional manufacturing methods. Not only does this technology improve patient outcomes, but it also provides a more sustainable and cost-effective solution for the medical industry as a whole.

In addition to jewelry and medical devices, 3D printing is being used in a variety of industries to create unique and innovative products. From aerospace components to architectural models, the possibilities are endless.

As technology continues to evolve and become more accessible, the potential for 3D printing to transform various industries is greater than ever before.

How 3D Printing is Transforming the Architecture and Construction Industry

The advancements made in 3D printing technology have opened up a whole new world of possibilities for architects and the construction industry. 3D printing in the field of architecture has transcended the boundaries and set a new dimension for construction, enabling a level of personalization and efficiency never seen before.

Customization and faster design – Traditional models of designing and constructing buildings would take years, but with the help of 3D printers, architects can print and evaluate their designs in a matter of hours.

The speed of the process offers the flexibility of getting iterations done quickly, allowing for the early identification of problems and easier corrections. Architects also have the ability to customize designs to an unprecedented level, with the help of 3D printing.

Eco-friendly and cost-efficient construction – 3D printing technology has opened new possibilities for sustainable architecture and eco-friendly designs. 3D printing reduces the amount of waste produced during construction, which makes it an environmentally-friendly alternative. It can also contribute to a reduction in construction costs by requiring fewer materials and labor.

With all these benefits, 3D printing has changed the way architects and the construction industry think about design, construction, and sustainability.

Although there is still much to be learned about this technology, the possibilities are limitless. The construction and architecture industry is poised for more exciting innovations in the years to come.

Creating Customized Prosthetic Limbs with the Help of a 3D Printer

Prosthetic limbs have been around for centuries, but with the advent of 3D printing technology, they are becoming more personalized and affordable than ever before. 3D printing allows for the creation of custom prosthetics that perfectly fit the unique shape and size of an individual’s body.

This technology has revolutionized the world of prosthetics, making it possible for amputees to have access to high-quality, customized prosthetics that were previously cost-prohibitive.

With 3D printing, prosthetic limbs can be created in a fraction of the time it takes using traditional processes, such as molding and casting. In addition, the materials used in 3D printing can be highly durable and lightweight, making them ideal for prosthetics.

The process of creating a prosthetic limb with a 3D printer begins with a scan of the amputee’s residual limb, which is used to create a 3D model.

Once the model is created, it can be customized to fit the specific needs of the individual. This can include adjustments to the length and width of the prosthetic limb, as well as modifications to the shape to better match the natural movements of the body.

The resulting prosthetic limb is not only functional but can also be aesthetically pleasing, with the ability to add custom designs or colors.

Overall, the use of 3D printing in the creation of prosthetic limbs is transforming the industry. It has made prosthetics more accessible and personalized, allowing amputees to regain their mobility and independence.

As technology continues to advance, it is likely that the use of 3D printers will only become more prevalent in the creation of prosthetic limbs.

The Future of 3D Printed Food: A Look into the Culinary Industry

3D printing has gradually made its way into the culinary industry, and it’s no surprise considering the amount of precision required in creating dishes. Food printing technology has advanced to a point where it’s not only feasible, but it’s also becoming increasingly popular.

One of the benefits of 3D printing in the food industry is that it allows for the creation of shapes and designs that aren’t possible through traditional methods. This technique saves chefs time and gives them the opportunity to dream up new and unique edible creations.

One major benefit of 3D-printed food is the ability to customize ingredients based on dietary restrictions or preferences. For example, someone with a gluten intolerance could have a meal specifically printed with gluten-free materials. It’s also a great solution for people with allergies who may need to avoid specific ingredients.

This type of technology means that people can enjoy meals that are tailored to their specific needs in a way that was not possible before.

Another exciting aspect of 3D-printed food is the ability of labs and research centers to create new textures in food. With 3D printing, you can create complex shapes and textures that wouldn’t be possible with traditional cooking techniques.

This opens up huge creative opportunities for chefs and food companies in creating new and exciting food experiences for their customers.

While the 3D printing of food is still in its early stages, it has a bright future in the culinary industry. In the coming years, we can expect to see 3D-printed food on menus and in grocery stores.

As technology advances and becomes more widely adopted, 3D printing technology is poised to change the way the food industry operates forever.

Breaking Boundaries with 3D Printing: Exploring the Limitless Possibilities

This section aims to explore some of the most exciting and futuristic possibilities of 3D printing technology. While we’ve already discussed how 3D printing is being used in various industries, this section will take a look at some of the groundbreaking ways researchers, innovators, and scientists are using 3D printers to push the current limits of technology and create new and innovative products.

1. 3D Printed Homes: Building the Future

One of the most exciting possibilities of 3D printing technology is its potential to revolutionize the construction industry. Scientists and engineers are continuously working on developing 3D printing technology to create entire houses and buildings, which could reduce construction costs and make housing more affordable for people worldwide.

In fact, the world’s first 3D-printed community of homes was successfully completed in Mexico, and the results were remarkable.

Another exciting development is the use of 3D printing to create sustainable housing alternatives. Researchers at the Massachusetts Institute of Technology (MIT) have developed a technique for printing houses out of natural materials, such as wood and clay, which could help reduce the environmental impact of traditional construction methods.

2. Personalized Medicine: Custom-Made Solutions for Patients

One of the most promising and fascinating applications of 3D printing is in the field of medicine. With 3D printers, scientists can create custom-made implants, prosthetics, and even organs, that perfectly fit a patient’s unique anatomy.

This technology has already proven to be revolutionary in the medical industry, allowing doctors to create precise and personalized solutions that weren’t possible before.

For example, doctors have used 3D printing to create prosthetic limbs that are custom-designed to fit a patient’s body, providing better comfort and functionality. Researchers are also exploring the use of 3D printing to create new skin grafts for burn victims and even organs for transplantation, which could significantly reduce the organ donor shortage crisis.

3. Aerospace Innovation: Reshaping Space Exploration

Another exciting field that’s pushing the boundaries of 3D printing technology is aerospace. 3D printing has already been used to manufacture rocket engines, satellites, and other space hardware, but the technology’s potential for space exploration goes beyond the production process.

One of the most interesting possibilities of 3D printing in aerospace is space habitat creation. 3D printing can allow astronauts in space missions to create necessary tools and objects from scratch, rather than relying on pre-made equipment.

Moreover, 3D printing can be used to create bases or habitats on uninhabitable planets and moons, which could allow for longer space missions and even colonization.

In conclusion, 3D printing technology is quickly reshaping various industries, enabling professionals to create innovative solutions and push boundaries. From healthcare to aerospace, and from construction to culinary, 3D printing has limitless possibilities that we are only beginning to explore. As technology continues to evolve and improve, we can expect more exciting breakthroughs and achievements in the near future.

People Also Ask

What is a 3D printer?

A 3D printer is a machine that can create physical objects from digital models. It works by layering materials, such as plastic or metal, until the desired shape is formed.

What are the benefits of 3D printing?

Some of the benefits of 3D printing include the ability to create complex and customizable designs, reduced costs for prototyping and production, and the potential for on-demand manufacturing.

What materials can be used in 3D printing?

A wide range of materials can be used for 3D printing, including plastics, metals, ceramics, and even food. The specific materials used will depend on the printer and the desired result.

What industries use 3D printing?

3D printing is used in a variety of industries, including aerospace, automotive, healthcare, and architecture. It is also used in art and jewelry making, as well as for hobbyists and makers.

What are some examples of things that can be 3D printed?

Some examples of things that can be 3D printed include machine parts, prosthetics, jewelry, toys, sculptures, and even entire buildings.

Conclusion

In conclusion, 3D printing has revolutionized the way we think about manufacturing and design. From creating complex and unique structures to producing spare parts on demand, the possibilities of 3D printing are truly endless.

With ongoing advancements in technology and materials, it is exciting to imagine what the future holds for this innovative industry.